Published: 1.12.2022 by Alex Servais

After most of the participants had arrived a day or two beforehand, the course finally started on Tuesday, November 15th. First, we had breakfast together in the workshop and shortly afterwards we started the theory lessons with Heiko “Spargel” Wolff, who passed on his knowledge about the maintenance of aircraft in FRP construction. These lessons took place each morning for the first four days and, among other things, the different types of fibres which are used in glider construction were explained. For example, one property of carbon fibre is that it is very stiff compared to fibreglass, but it is stronger and lighter. In addition, he explained how to conduct proper maintenance work on gliders.

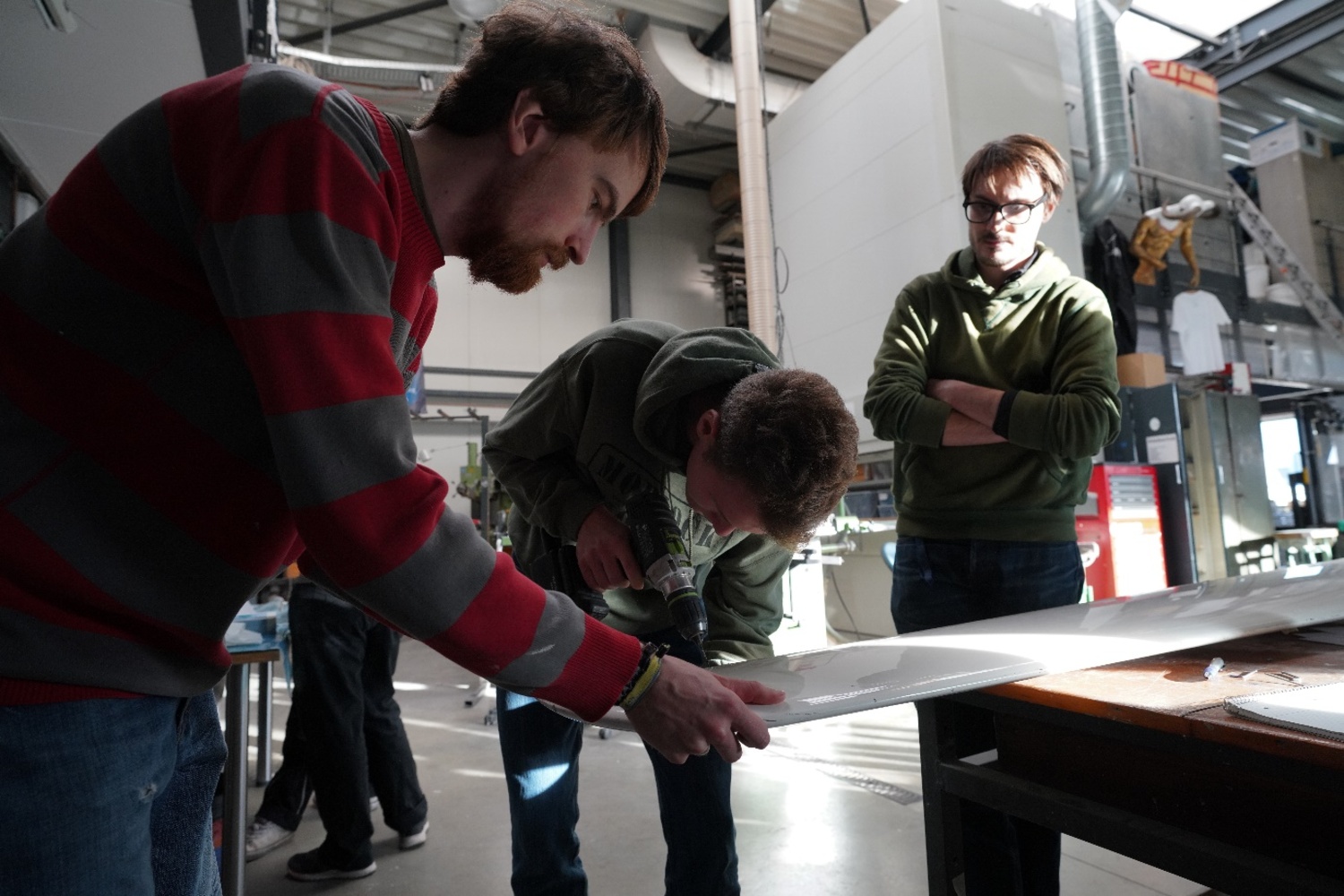

In the afternoon, the tools were unpacked, and the dungarees pulled on, so that the theoretical knowledge could be put into practise. A total of 5 workshops were held over 4 days. Workshops included wire fuses, determining residual rudder torque, lamination, shafting and polishing/sanding/etc. Shafting is a repair method that must be carried out when damage occurs in fibre composites.

At the weekend, our former member Emil “Teflon” Pluta gave a theoretical unit with the aim of learning all the legal aspects of maintenance. You could thus find out which repairs you are allowed to carry out by yourself and for which you need an external auditor who approves the work. In addition, the differences between LBA, DAEC, BFU, CAO, CAMO and all other organisations and abbreviations were explained, so that all participants are now fluent in the language of maintenance and repair law.

All in all, it was a successful course in which everyone learned a lot. We are already looking forward to next year, when the next Basic Sailplane Maintenance Course is due and the coming winter maintenance, in which every participant can apply what they have learned.