Published: 31.10.2019 by Benjamin Kelm

An important element of the pioneering FVA 30 project is the propeller. On the one hand, environmentally friendly flying depends to a large extent on the performance efficiency of the flying object. At this point, an optimized propeller offers a high potential to save energy, which is why efficiency is an important design criterion when determining the appropriate geometry. On the other hand, advanced, low-emission flying involves not only optimizing performance and reducing pollutant emissions, but also reducing noise emissions. A Matlab tool for the simulation of propeller noise was designed in advance for the FVA 30, which also included a simplified method for performance calculation.

Threedimensional propeller geometry wireframe

In the context of the propeller design it was necessary to start at this point last year and to design a propeller on the basis of the mentioned aspects regarding efficiency and noise and also to validate it under consideration of structural aspects.The self-imposed goals of finding a propeller geometry optimized for the FVA 30 by the end of the summer semester 2019 and establishing industrial contacts for the production of the propeller could be successfully achieved. First, the performance calculation of the self-implemented propeller analysis tool was made more detailed and the calculation method based on the blade element theory was extended by some realistic corrections. For this purpose an interface to the flow analysis program XFOIL was implemented in order to directly integrate a calculation of the coefficients of lift and drag along the geometry to be analyzed as accurately as possible. Furthermore, the widely established JavaProp pre-design program was widely used as an important tool for the generation of preliminary propeller geometries and for result validation.

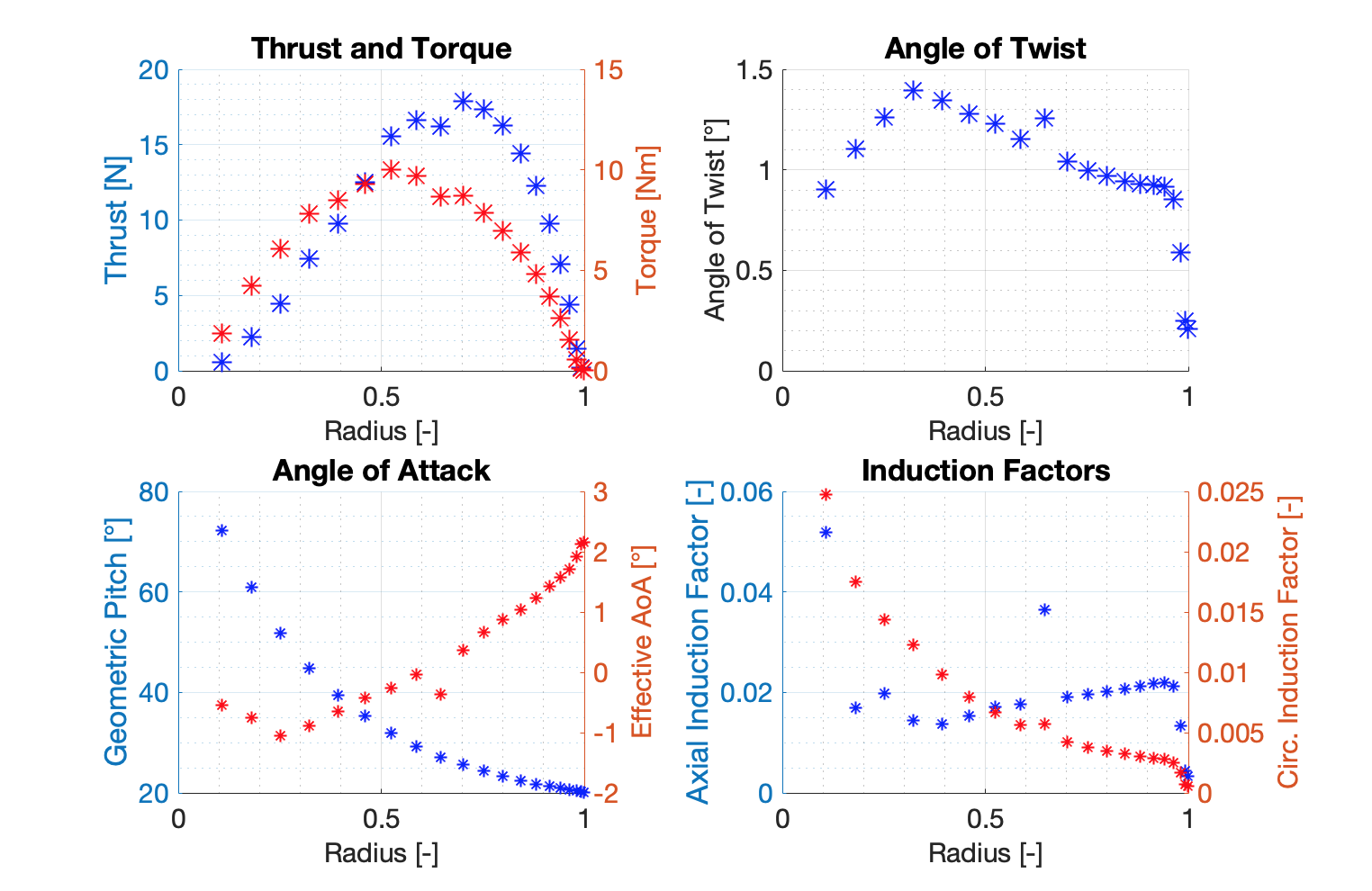

Current FVA 30 Propeller Aerodynamic and Performance Plots

The choice of climb flight as the design point of the propeller quickly proved to be the most efficient variant compared to take-off and cruise flight. After extensive testing of the program and various parameter variations, a geometry could be found at the end of the design phase that meets all design points. Due to a relatively large blade radius of 1.4 m, the speed can be kept low, which greatly improves the efficiency and the noise efficiency. The low-loss, slim profile also meets the structural requirements. The propeller provides sufficient thrust in all flight phases and undercuts the set target of a noise level of 60 dB-A when taking off at a distance of 200 m with a calculated noise level of approx. 43 dB-A. The propeller is designed for a low loss, slim profile and also satisfies the structural requirements. After successfully designing the propeller, Helix Carbon GmbH was found as a well-known and extremely courteous industrial partner, who agreed to work closely with the FVA on the production of the propeller and, in the name of research, also to provide some data and know-how to further improve the calculation method at the FVA. During a guided tour through the production facility with a previous discussion, some valuable insights into the construction of propellers could already be gained. We hope to intensify the contact in the coming year and possibly to establish a lasting cooperation.